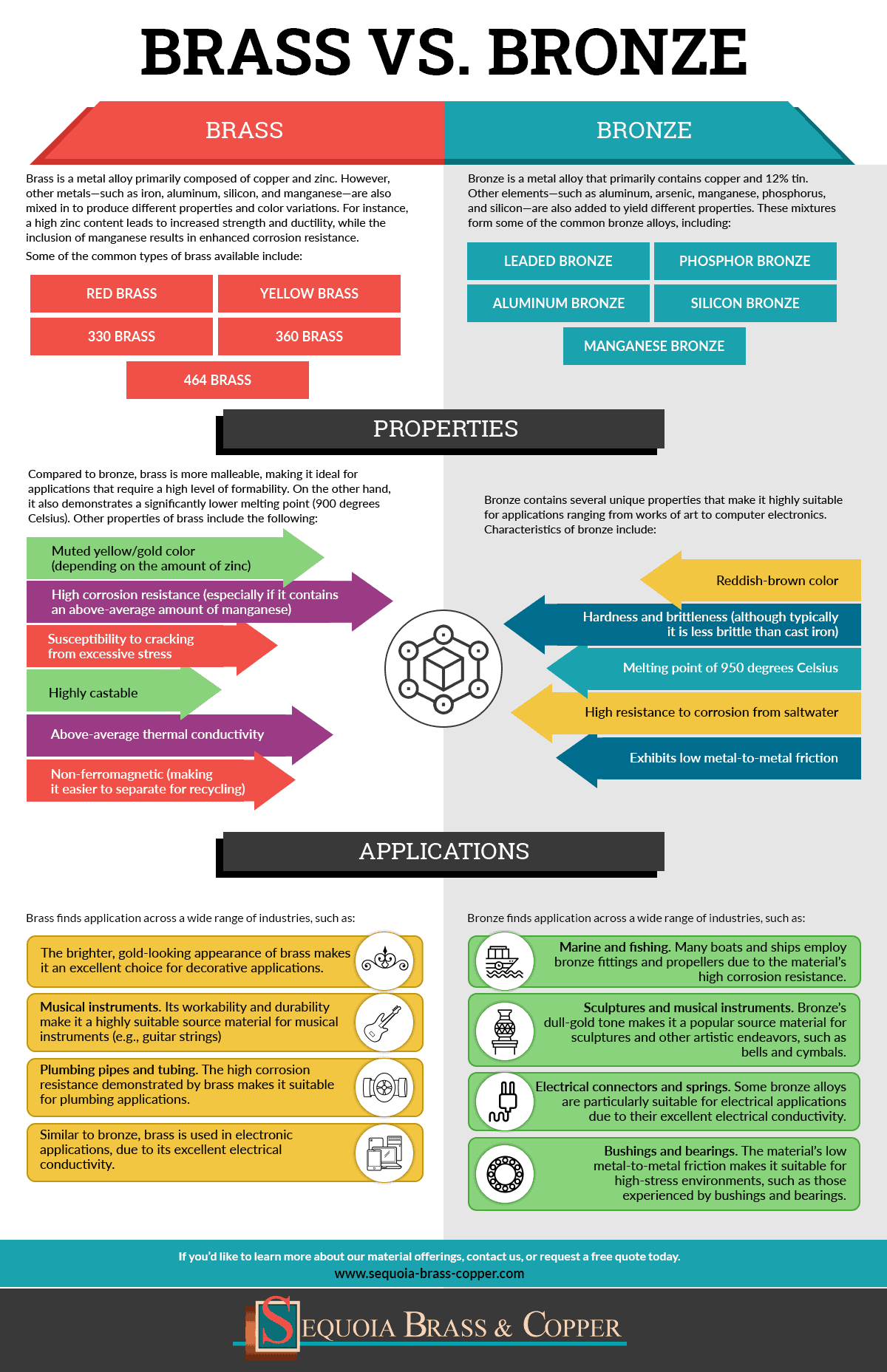

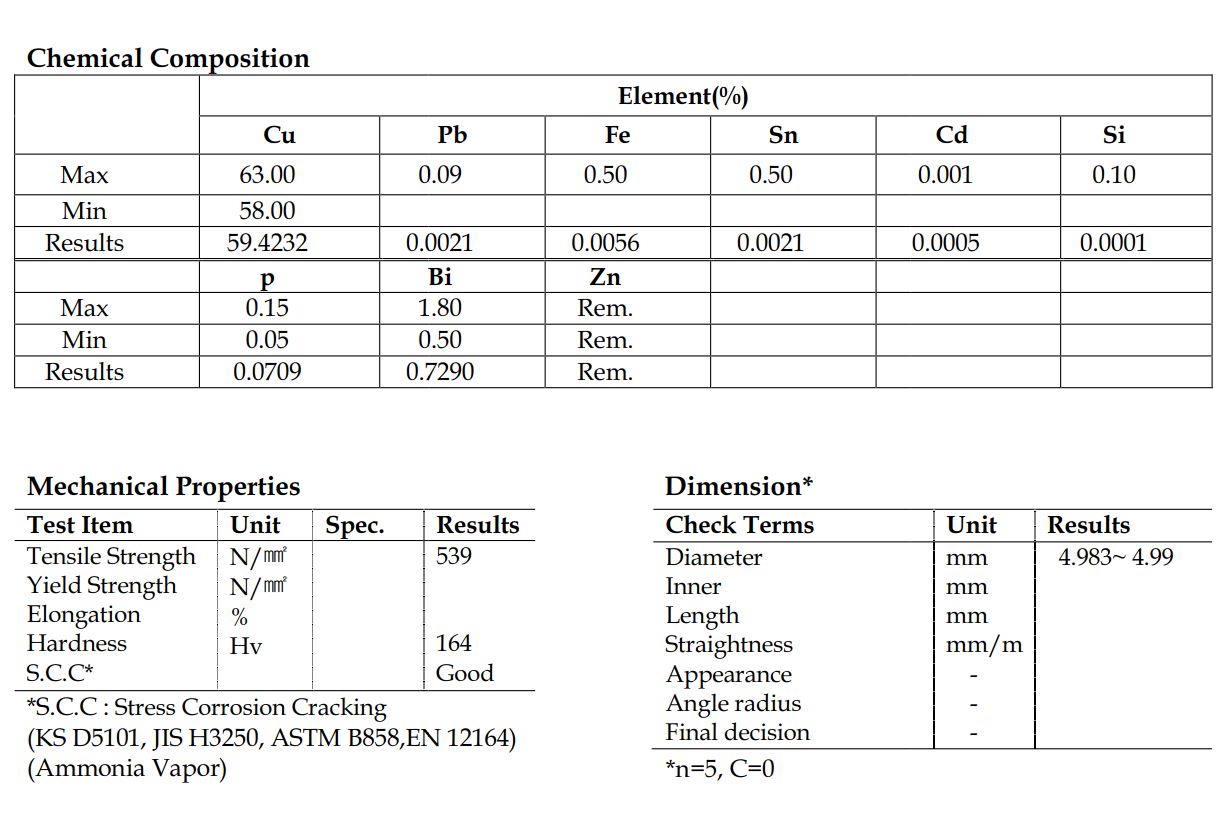

Chemical composition of the lead-free brass

Download Table | Chemical composition of the lead-free brass from publication: Modified Johnson–Cook flow stress model with thermal softening damping for finite element modeling of cutting | Results of materials testing for lead-free brass show that the effect of thermal softening decreases significantly when the strain rate is high. This behavior is referred to as thermal softening damping. In this article, a flow stress model with thermal softening damping | Damping, Thermal and Finite Element Modeling | ResearchGate, the professional network for scientists.

A sketch of the conical tank's vessel. Fig. 12. A 16×16 finite element

Meridional stresses in concrete (under ultimate loads).

Reinforced concrete slabs under different loadings.

Wieland-M42 – lead-free machining brass

C4926 Lead-free Brass Rod - Products

USA Made Lead Free Solder,Safety High Strength Nicke-Bearing

Modified Johnson-Cook Flow Stress Model With Therm, PDF, Deformation (Engineering)

Meridional stress distributions at steel bars for tanks T7, T8, and T9

dzr brass, eco brass, rods, tubes, hollow, section, manufacturer

:max_bytes(150000):strip_icc()/10075603-56a613df5f9b58b7d0dfcc53.jpg)

Composition of Common Brass Alloys