Why You Must Optimize Cooling and Venting in Plastic Injection Molds

Learn about the importance of optimized cooling and venting in plastic injection molds to avoid issues such as short shots, flash, or excess cycle times.

Back to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

How to improve the life of plastic injection mold?

Tips For Plastic Injection Molders-Topworks Plastic Polding

Why You Must Optimize Cooling and Venting in Plastic Injection Molds

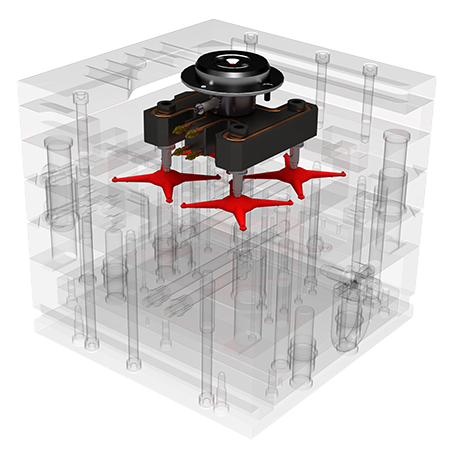

A Different Approach to Mold Venting

Venting Solutions - DME

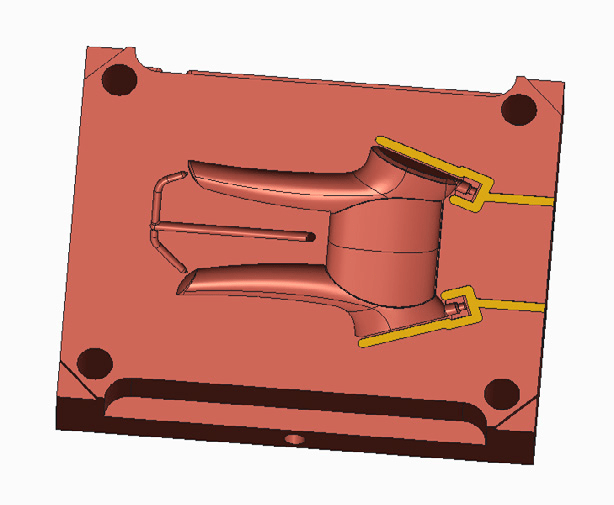

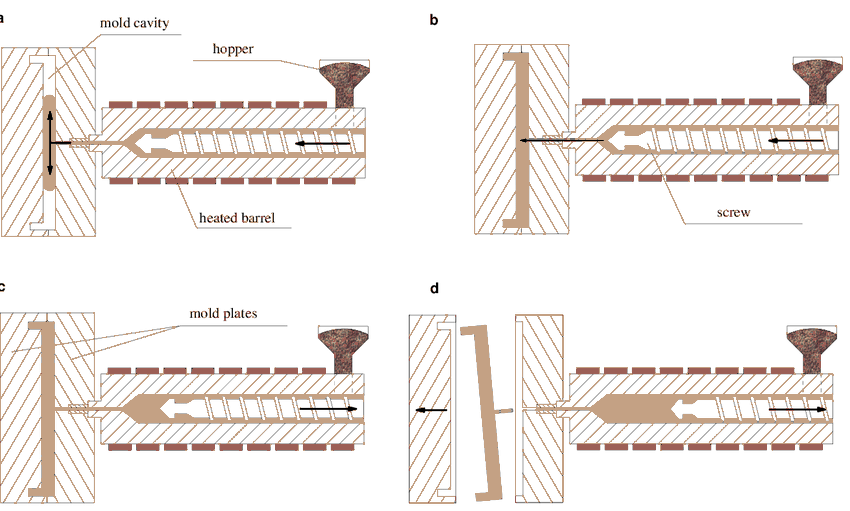

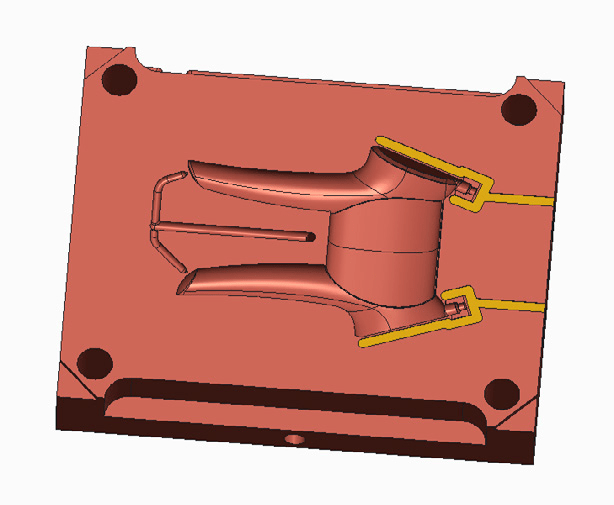

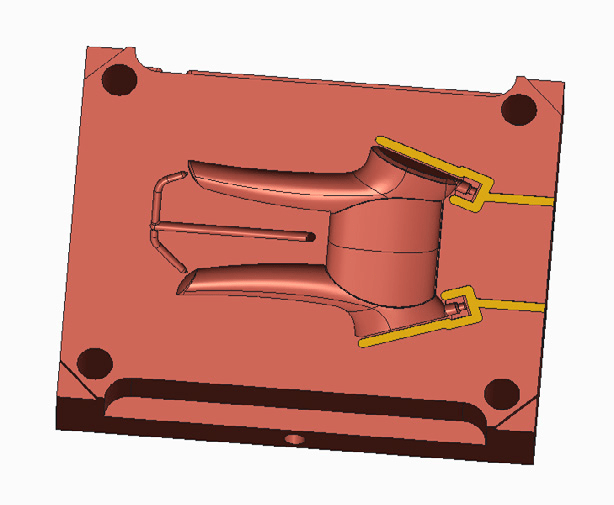

Parts of an Injection Mold: Exploring Their Components and Design

Mold Venting System & Design Principles - Ecomolding

Why You Must Optimize Cooling and Venting in Plastic Injection Molds

A Different Approach to Mold Venting

Our Best Tips for Designing Your Injection Mold

13 Possible Injection Moulding Defects And How To Avoid Them - Unipipes

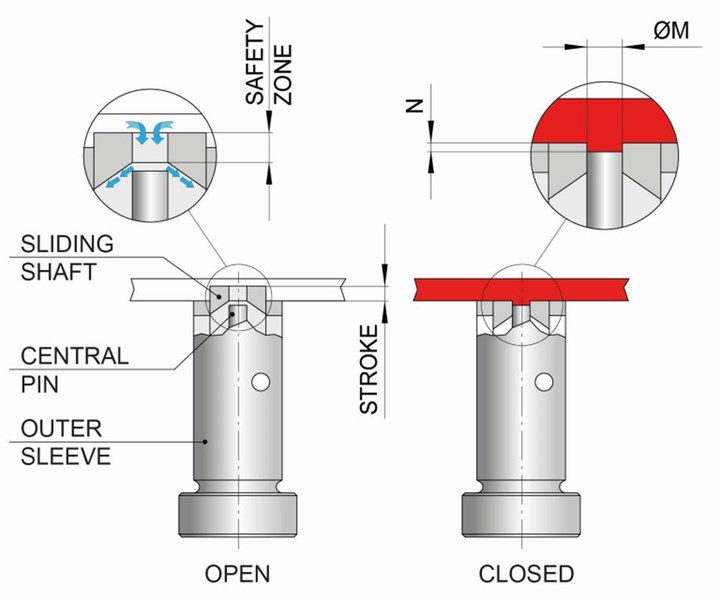

Mechanical modifications in the inferior cavity of the mold: air vents

Thin Wall Injection Molding Considerations

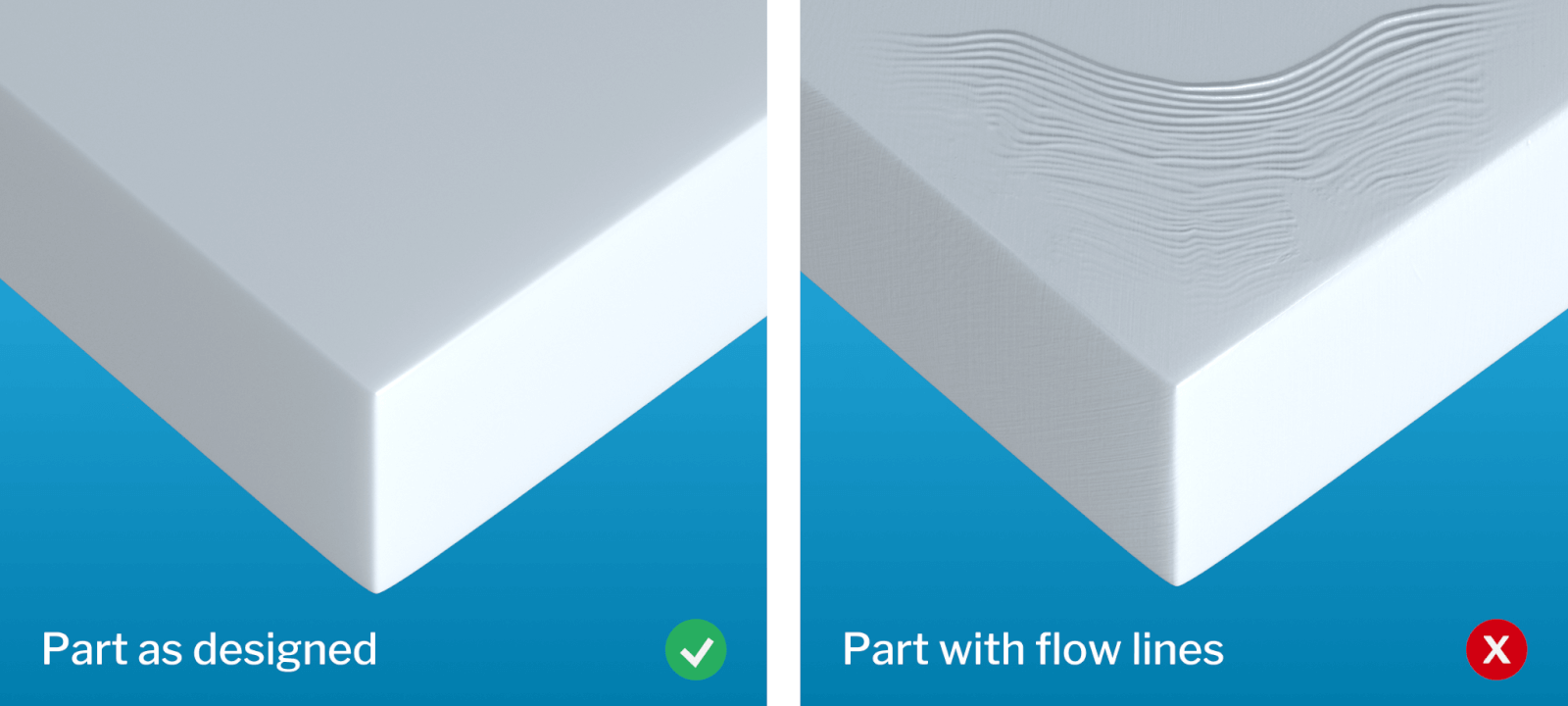

How to avoid injection molding flow lines