Threaded Holes: An Introduction and Guidelines

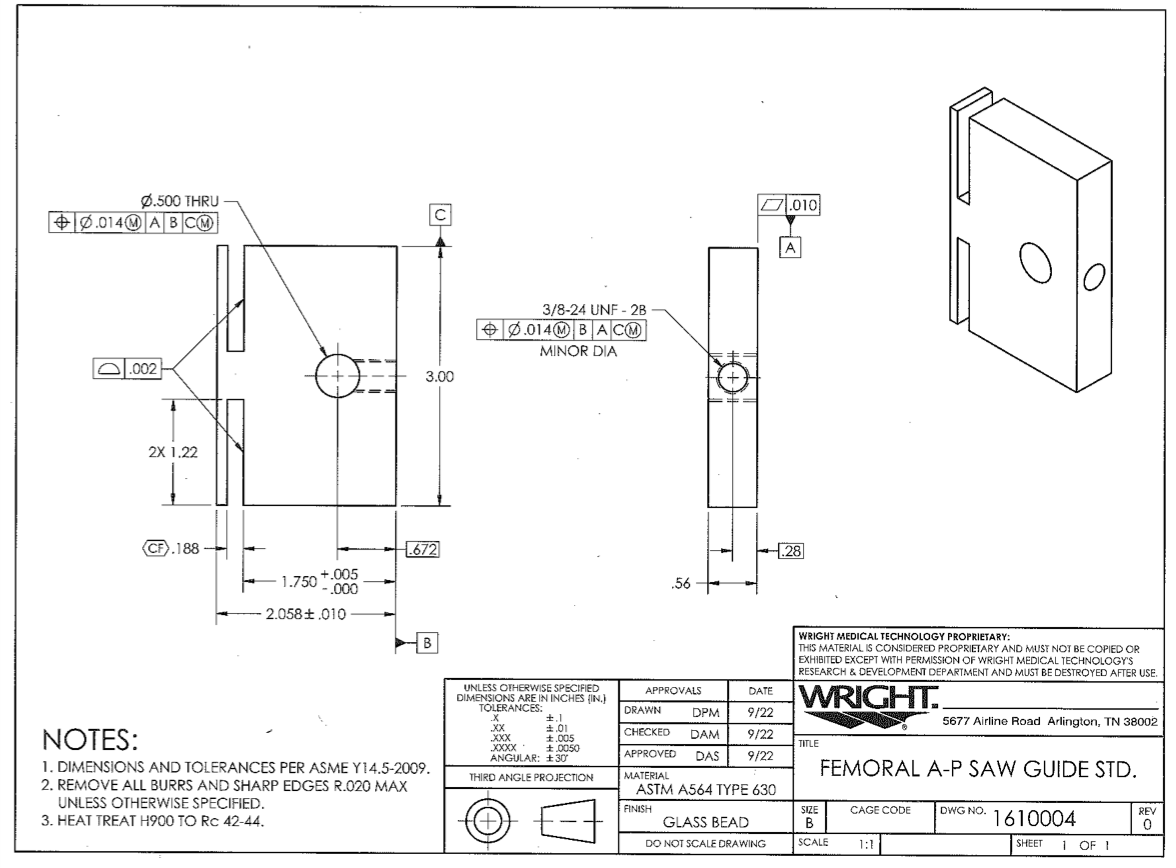

Threaded holes are integral aspects of mechanically fastened parts. They are easy to add with CNC machines. Threads are usually added last after most other aspects of the part have been machined. Getting it wrong and being forced to scrap a part can be a very costly mistake. There are several factors designers and machinists must consider when they approach threaded components. Careful planning along with the following guidelines will make the addition of threaded holes go smoothly.

Solved Question 4 On the Femoral A-P Saw Guide Std., what

The novel skin-stretching device, BHS. a Threaded rod cap, b

Adjustable spring-tensioned tap guide is used with a tap to thread holes in machining operations Tap guide aligns tap with the center of the hole and

Spring Center Knurl Tap Guide Tool to Align Tap for Threading Lathe Mill Jig Bore

Conical body made of high-quality synthetic material with cylindrical geometry Steel drilling socket with 8 mm diameter Threaded construction for easy

wolfcraft Hole Saw Guide for Hole Saws Diameter 46 - 62 mm I 5951000 I Hole Saw Guide for Centered Widening of Existing Holes

LOCTITE Threadlocker Application Guide for Better Threaded

Make Threaded Holes: Considerations For Tapped A Hole - WayKen

GRS-16 PE Template for Adding M6 x 1.0 Tapped Holes

Linear Ball Slide Guides - with Counterbored or Tapped Holes

Brewer Sewing - NEEDLE CLAMP Round Hole thread guide zig zag