Wire Forming: What Is It? How Does It Work? Types & Uses

Multi-chapter guide to Wire Forming describing: what is a wire forming, how wire forming is done, types of wire forming, how wire formed wires are used.

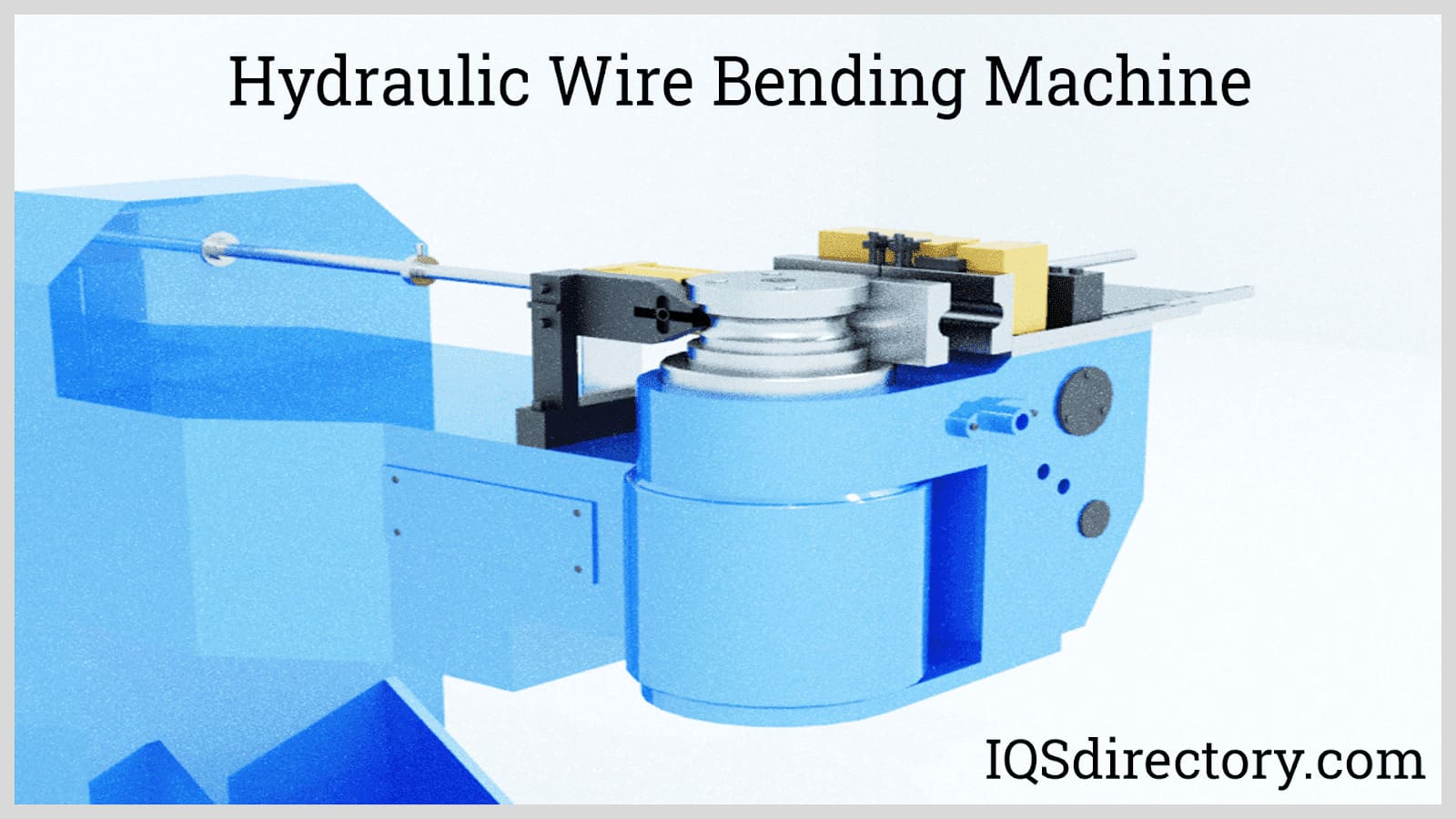

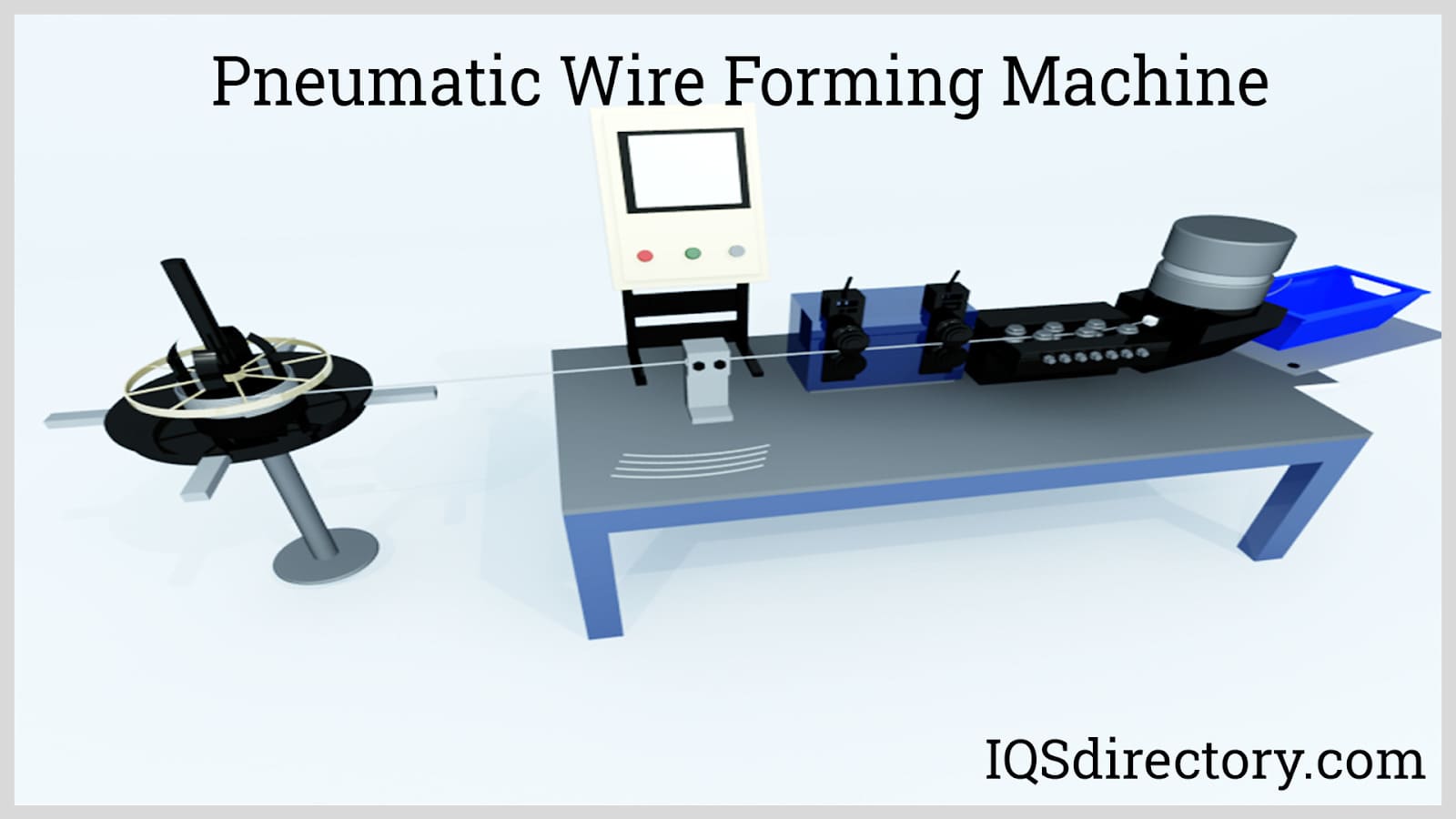

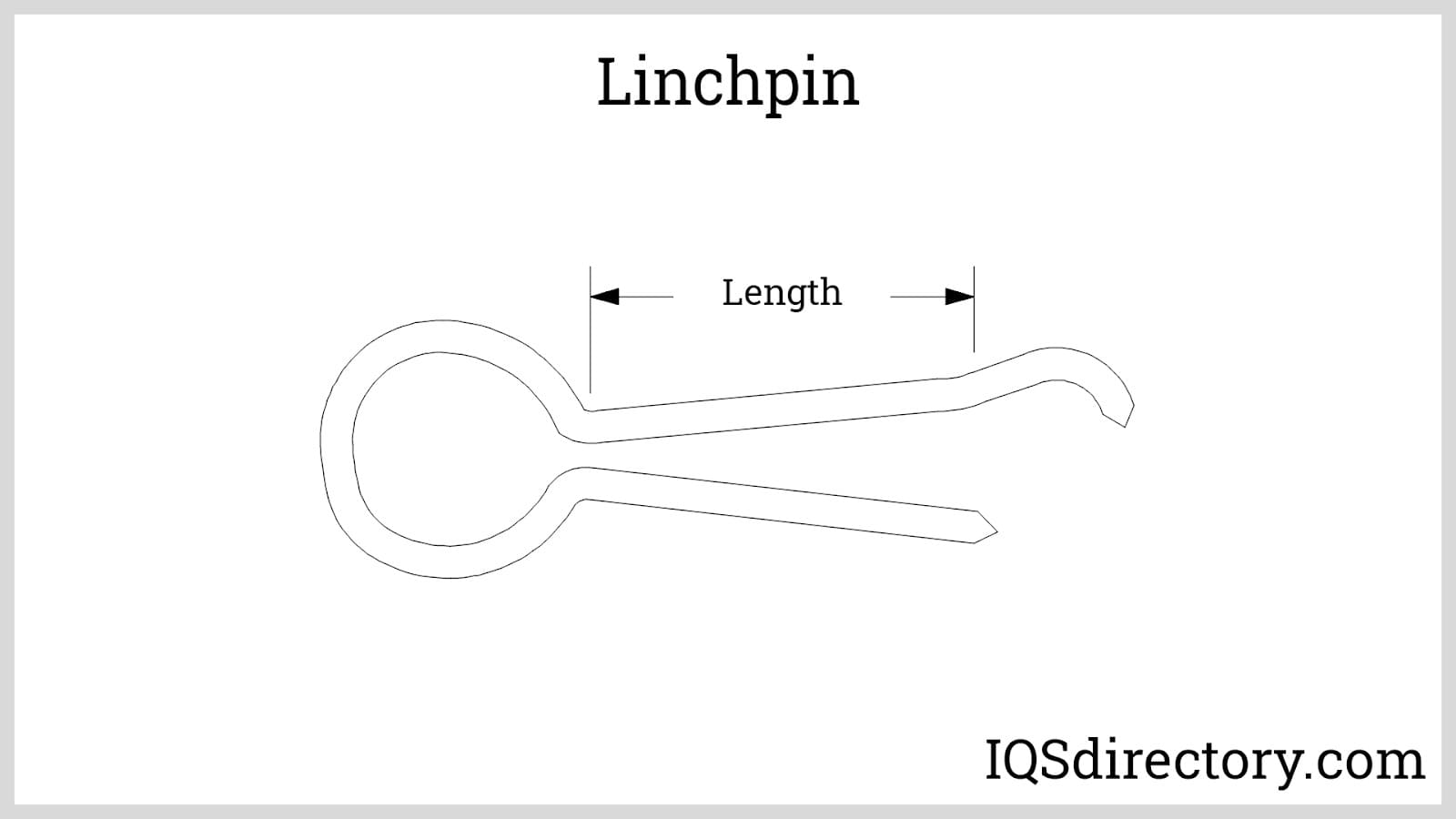

Wire forming is a method for applying force to change the contour of wire by bending, swaging, piercing, chamfering, shearing, or other techniques. The various techniques for wire forming can produce any type of shape, form, or configuration. The process starts with coiled wire that is straightened before being formed. Common metals used for wire forming include steel, brass, stainless steel, copper, aluminum, and a variety of different alloys. The diameters of wires vary from 0.5 mm to 6.5 mm, or 1/64th of an inch to a quarter inch and can produce 2 and 3 dimensional wire forms. The types of equipment to complete wire forming vary between manual crafting to advanced CNC programmable machines. The process includes options for coating and protecting final products for use in harsh conditions.

Types of Electrical Wires and Cables - The Home Depot

:max_bytes(150000):strip_icc()/nonmetallic-cable-sheathing-color-1152905-final2-c48c6eee82ab43b9ad6c15bbc473c839.jpg)

Color Coding of Nonmetallic (NM) Electrical Cable

:max_bytes(150000):strip_icc()/electrical-wiring-1152909_hero_3222-55af500248d646a9adc653a0dba5f14c.jpg)

All About Electrical Wiring Types, Sizes & Installation

Wire Forming: What Is It? How Does It Work? Types & Uses

:max_bytes(150000):strip_icc()/wiretransfer-FINAL-8fb2c62ec7e7410792ebb33a8c82ddb9.jpg)

What Is a Wire Transfer? How It Works, Safety, and Fees

/wp-content/uploads/2019/07/galva

:max_bytes(150000):strip_icc()/payment.asp-Final-25aad0eedda34c9db463c665991c6323.jpg)

Guide to Payment Types, With Pros and Cons for Each

Wire Forming: What Is It? How Does It Work? Types & Uses

Parts of an electrical cable

Types of Cables and Connectors in Networking - The Home Depot

What are wireframes and why are they used?, Wireframing Academy

What is Wire Forming? - Salco Engineering & Manufacturing

What Are the Most Common Uses of Wire Forms?