3D Printed Tooling Supports Prototype Foam Seating

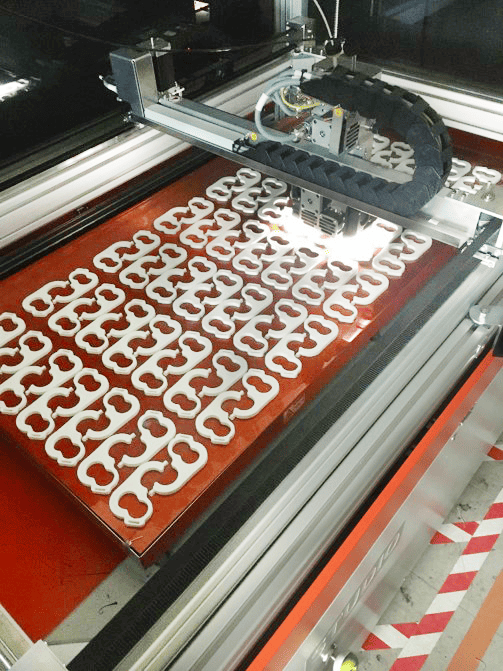

3D printed tools could be a faster, more affordable way to prototype and produce foam parts for automakers and other OEMs.

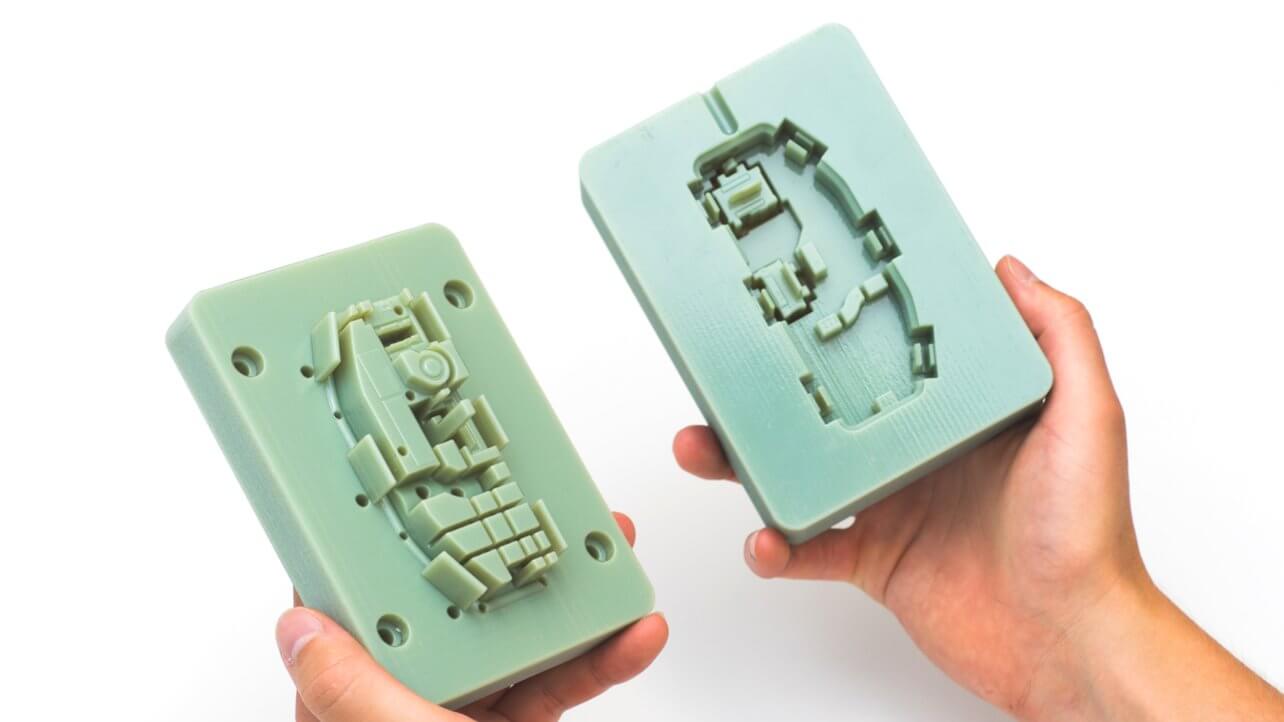

Automotive manufacturers and other OEMs require mold tooling to build foam components like seat cushions. 3D printed tools could be a faster, more affordable way to prototype and produce these parts.

Making life more comfortable for wheelchair-using individuals with a 3D- printed medical-grade cushion

Polymers, Free Full-Text

Graphene News and Updates - The Graphene Council

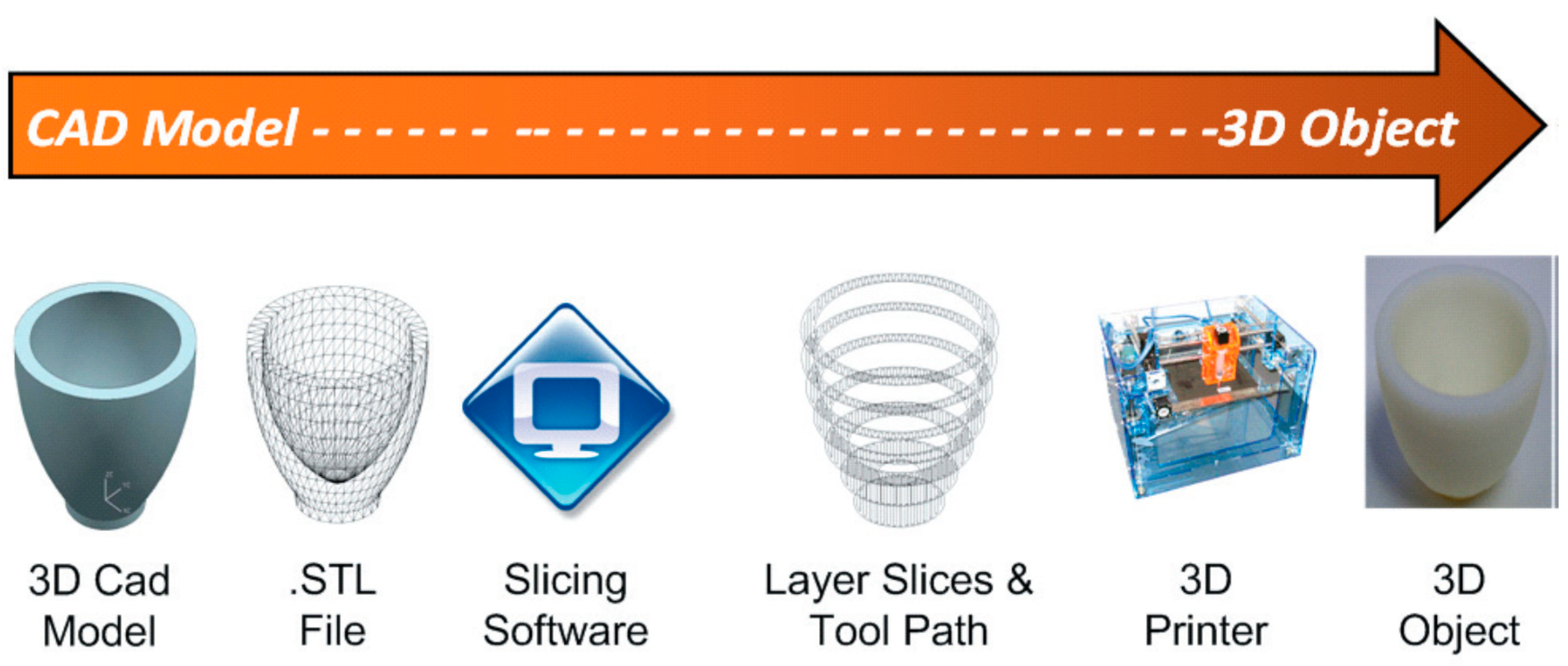

Utilization of 3D Printing on Large Scale for Manufacturing

5 Original 3D Printed MTB Accessories - Pinkbike

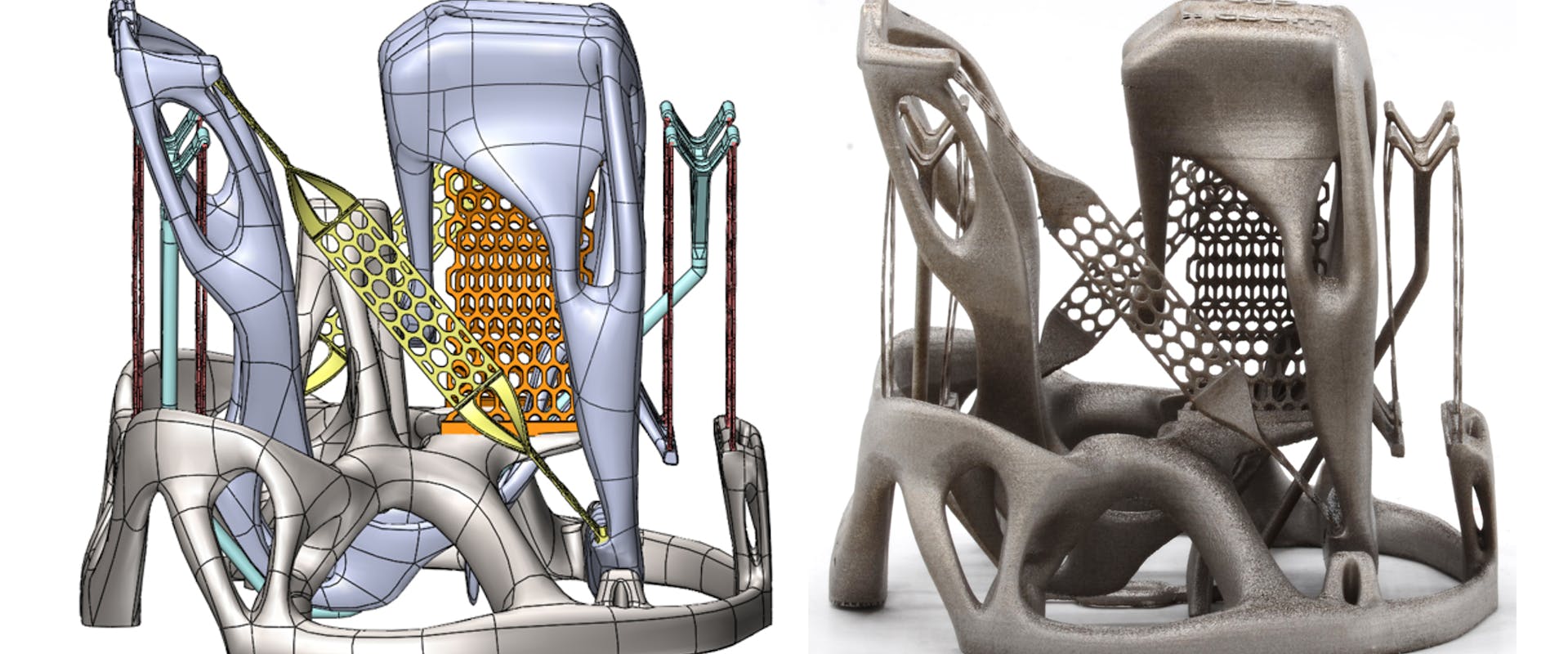

How 3D printed tooling can shape the future of prototyping

4 Ways Augmented Reality and 3D Printing Intersect

3D-Printed Prototype Molds Versus Aluminum Tooling

BigRep Industrial 3D Printers

3D printed seats - Create it REAL

3D Printed Tooling Supports Prototype Foam Seating

Foam Part Manufacturing Tooling - Catalysis Additive Tooling

3D Printing in Automotive

ExOne Acquires Freshmade 3D Assets

How Makra Pro Developed a Process for Foam Molding Using 3D Printed Molds