Why Use Lead Free?

Most of us know that that lead in products is not only harmful to the environment but can potentially cause some health risks. Therefore, unless leaded solder is necessary for your job or project, it is always safer to use lead-free solder. And, the good news is that there are many available lead-free solder variatio

Wire Content: Alloy Tin 99.3% Copper0.7% Product Parameters: Net Weight: 16oz Melting Point: 217 ℃ (422.6F), Do Not Contain Flux, Need To Use With

Lead-Free Solder Wire(Sn99.3Cu0.7) For Plumbing Solder/Stained Glass/Crafts/Jewelry 217℃ Melting Point 2.0MM No Flux,ROHS(16oz)

Pros & Cons: Lead-Free Ammo

Why Use Lead-Free Solder For Stained Glass and Giftware – Stellar Technical Products

Does your soldering job leak? Why is lead-free solder hard to work with? And new products to make life easier.

Article

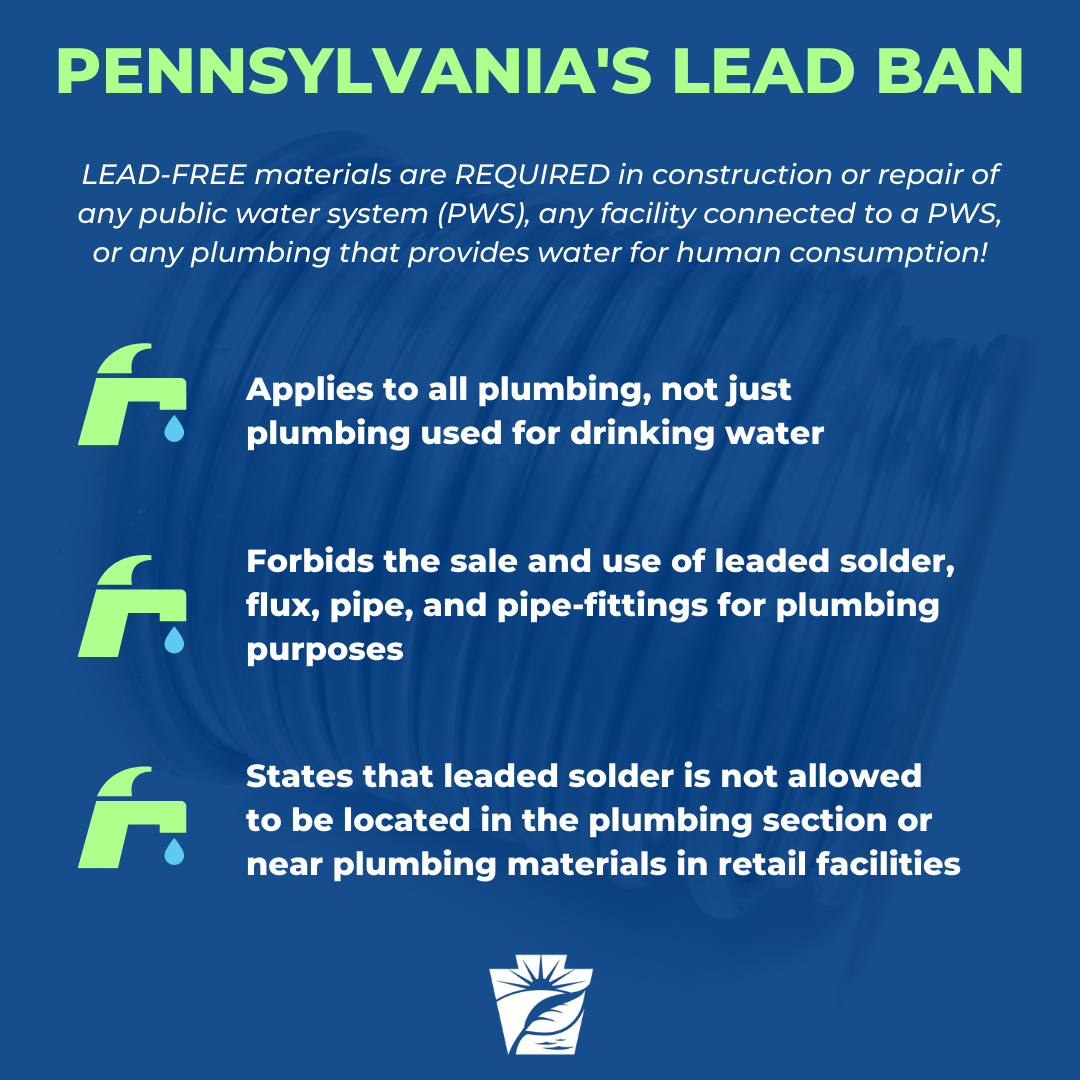

New California Law Requires Use of Lead-Free Plumbing Fixtures, 2021-10-12

PCB Manufacturing and Lead vs. Lead-Free Solder

What are the disadvantages of lead-free solder vs. lead solder?

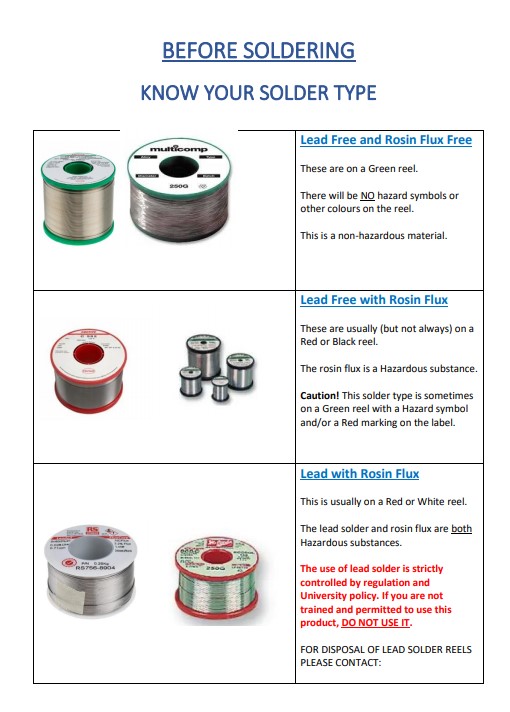

Soldering and Lead

Why Choose Lead Free Tapware?