Why is JBC a Better Soldering Solution? Here are 10 Reasons.

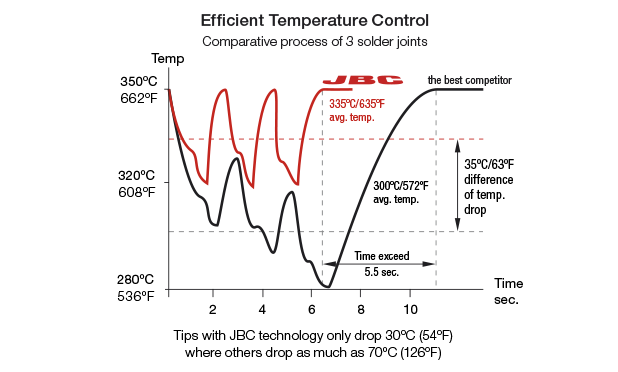

#1. Solder at Lower Temperatures The combination of High-Power Mass Ration Tips and an Integrated Heater / Thermocouple delivers lower soldering temperatures and the best thermal recovery in the market. JBC technology means tips only drop 30ºC (54ºF), where others drop as much as 70ºC (126ºF). This innovative technology allows a reduction of the temperature Read moreWhy is JBC a Better Soldering Solution? Here are 10 Reasons.

AMTEST - Ručné spájkovanie

Production Automation Corporation, Author at Technical Articles by

DMU Control Unit manages up to 4 tools simultaneously and is fully compatible with 10 different JBC tools. * MSE Electric Desoldering Module is

Premium ESD-Safe Digital 4-Port Precision Desolder/Rework Station

JBC BT-2SQA - Precision Analogue Soldering Station with T210

HDP Heavy Duty Tweezers Station has been designed to reduce the soldering time in applications that require a large amount of heatspan. * Some

Premium ESD-Safe Digital Heavy-Duty Tweezers Station

_Completa.gif)

C245730 - Blade Cartridge 10

Why is JBC a Better Soldering Solution? Here are 10 Reasons.

Why is JBC a Better Soldering Solution? Here are 10 Reasons.

JBC 120V Heavy Duty Station with T470 Handle - HDE-1D

Why is JBC a Better Soldering Solution? Here are 10 Reasons.

JBC Top 10 Reasons - JBC Tools

Electrical & Device Mfg. Archives - Technical Articles by

Newbie here) I tried tinning my tip with flux and solder, and