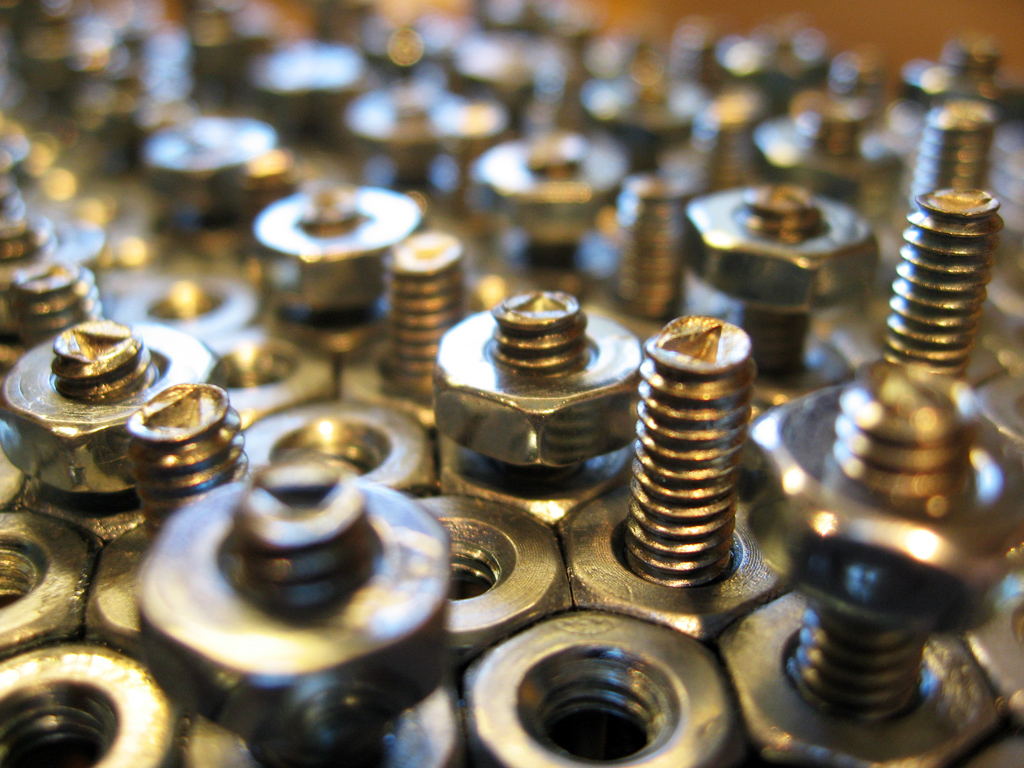

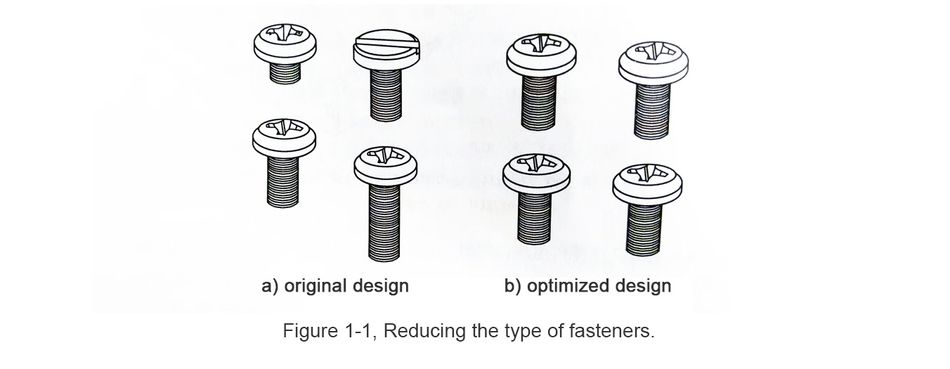

Design Guidelines for Manufacturing and Assembly - Reducing the quantity and type of fasteners

Are you aware of a component does not create added value, while is significant and indispensable for products? That is fasteners. For a product, a fastener only fixes the parts, and has barely no effect on the utilization.

DFMA Guidelines, PDF, Economic Sectors

Design for Assembly: assembly definition, part sequencing, product guidelines, part feeding and insertion, product redesign process, quantifying assembly improvement: 9781539423201: Zorowski, Carl F.: Books

Design for Assembly Principles: A Comprehensive Guide on DFA - WayKen

Wevolver Product Design Articles

Types of self-tapping screws for plastic and its characteristics

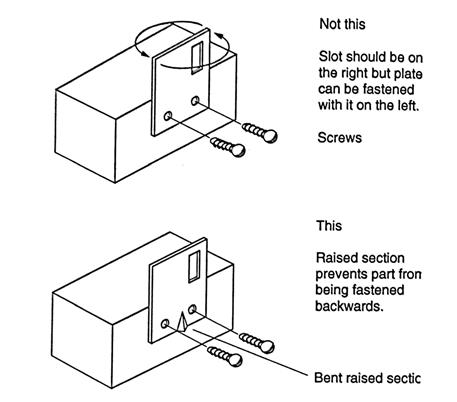

Design for Assembly: 12 Design Guidelines to Make Assembly More Efficient

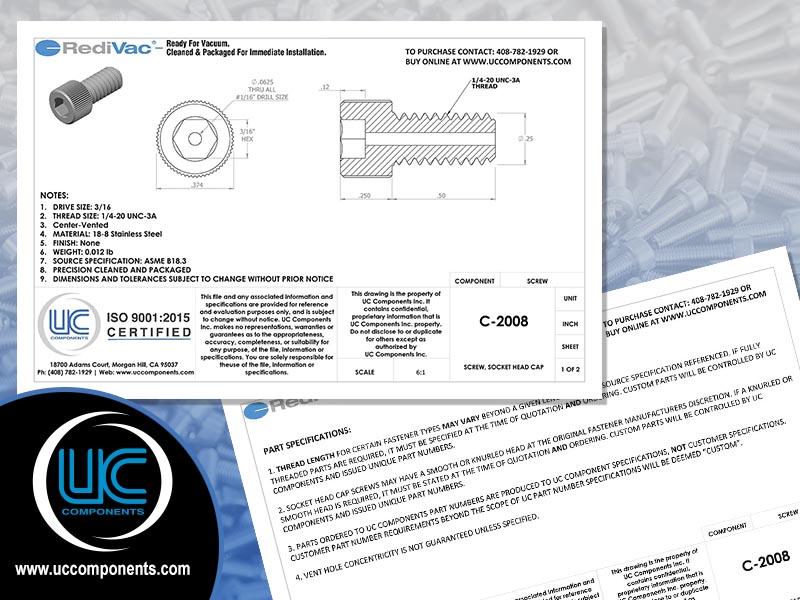

It is critical that you have a correct print for your fasteners, why? - UC Components, Inc.

Types of Rivets and Their Benefits in Rapid Prototyping and Manufacturing

Bolts vs. screws: What's the difference and when to use each

What Are Thread Rolling Screws And When Should You Use Them? - Accu

Wevolver Product Design Articles

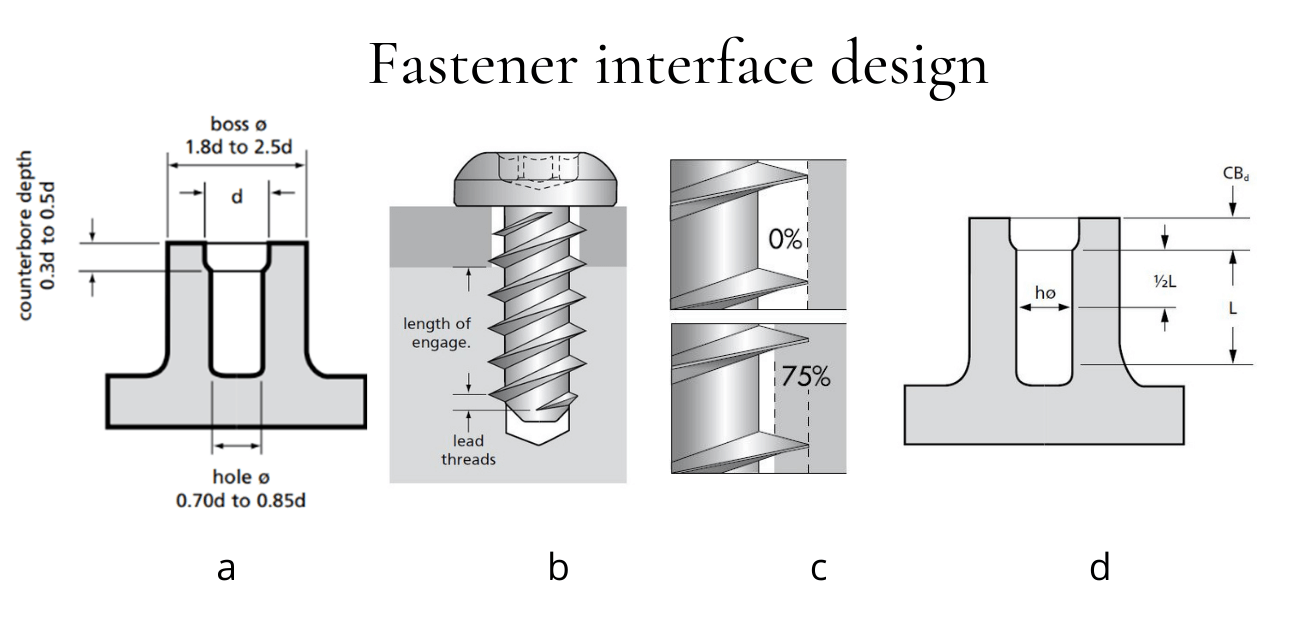

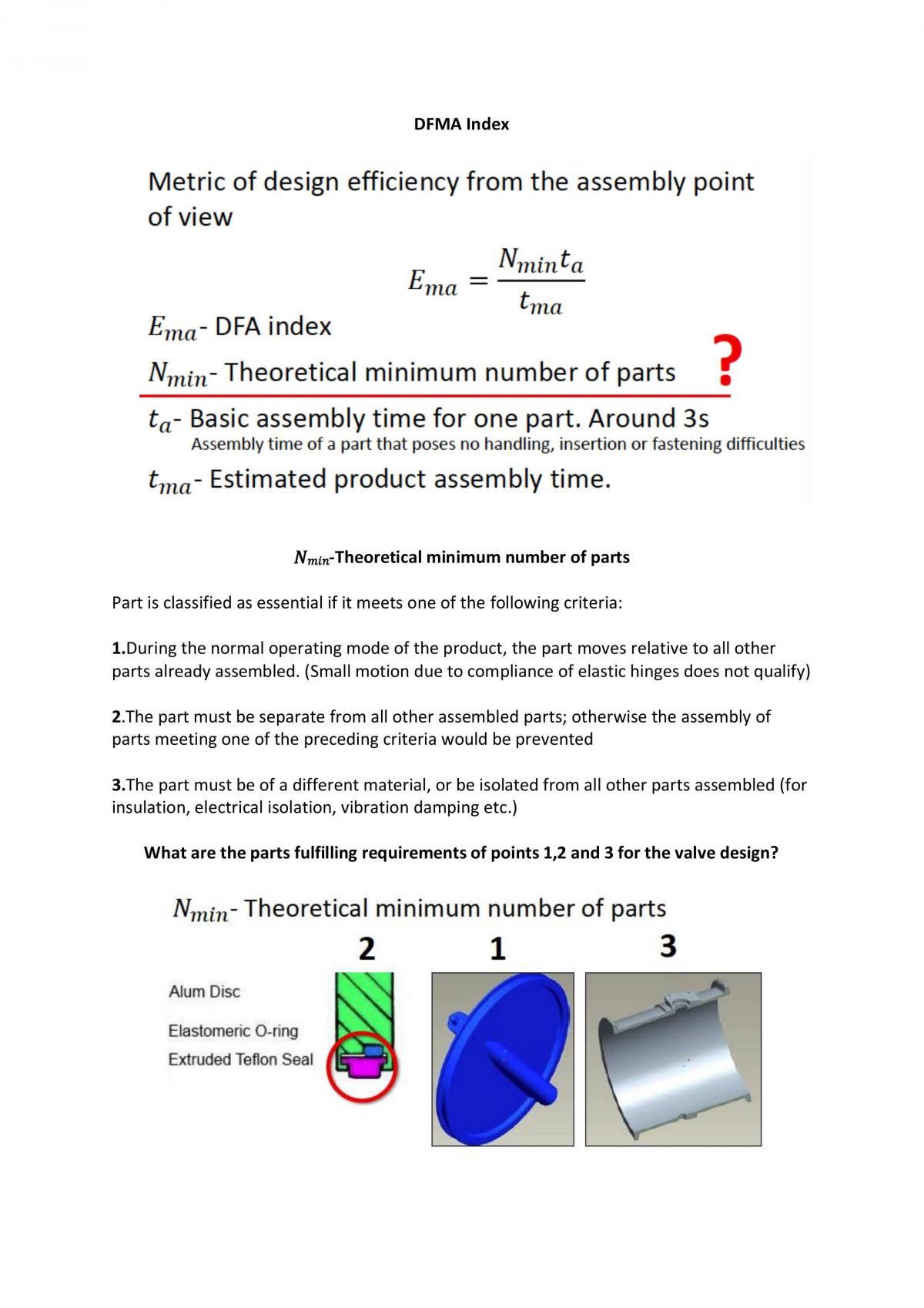

Manufacturing Engineering Design Complete notes, ES2D1 - Manufacturing Engineering Design - Warwick

List of top Asia-Pacific (APAC) 3D Printing Companies - Recent News & Activity

Design Guidelines for Manufacturing and Assembly - Reducing the quantity and type of fasteners

DFMA Tips