Wear and Scratch Evaluation of Surface Treated Copper Wire -NANOVEA

We simulate a controlled wear process of different copper wire surface treatments. Scratch testing measures the load required to cause failure on the treated surface layer.

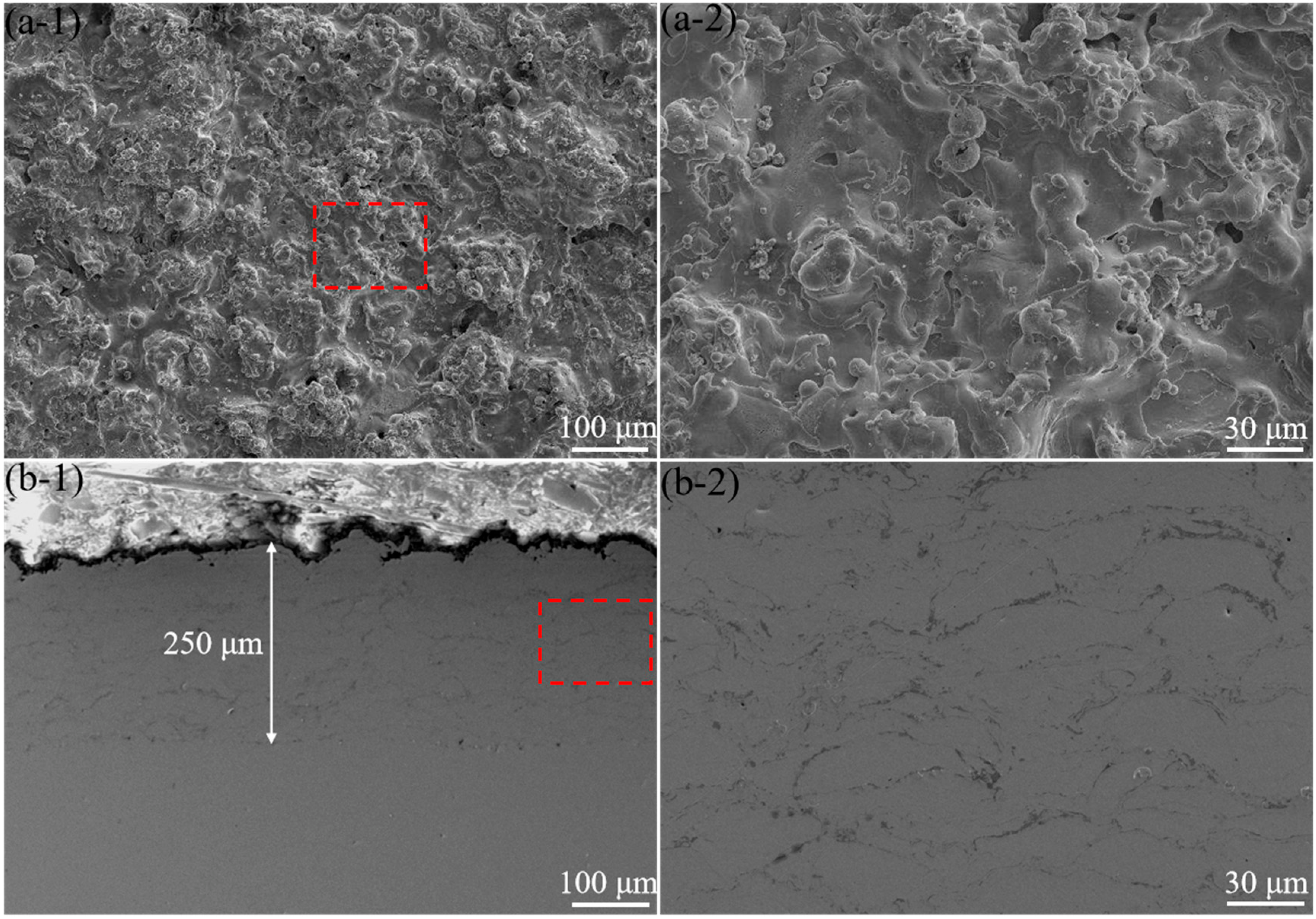

Fine-tuning effect of Direct Laser Interference Patterning on the surface states and the corrosion behavior of a biomedical additively manufactured beta Ti alloy - ScienceDirect

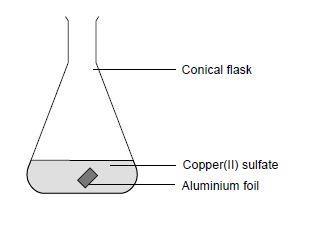

The reaction of aluminium and copper(II) sulfate, Experiment

Black Oxide Coating Finishing Ultimate Guide In CNC Machining

Corrosion behavior and wear resistance of Zr-2.5Nb alloy after thermal oxy-nitriding treatment - ScienceDirect

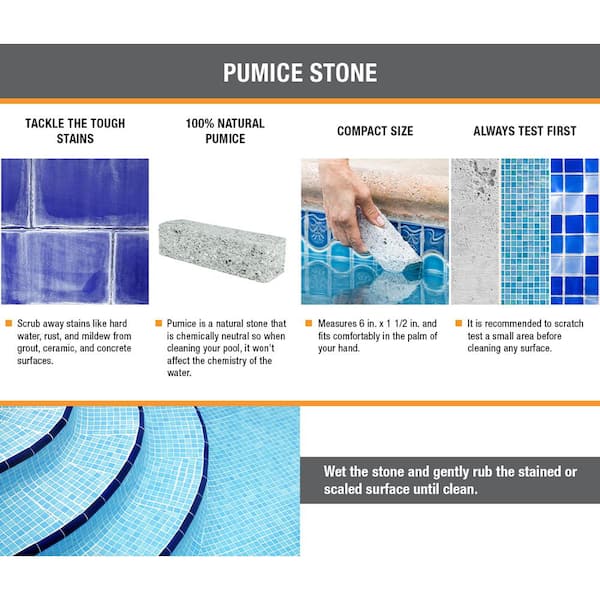

HDX Pumice Stone for Swimming Pools, Spas and other Surfaces 62665 - The Home Depot

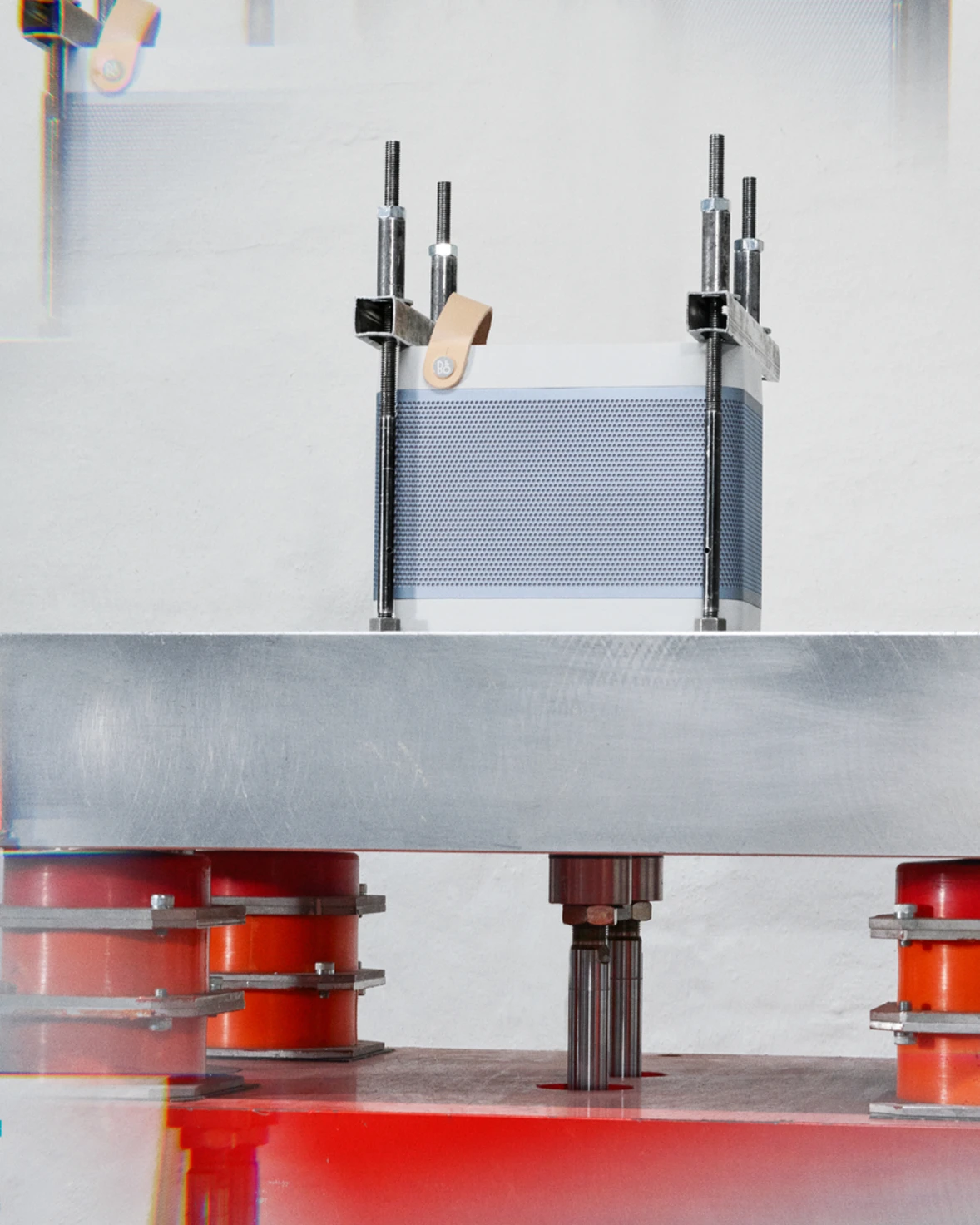

Wear and Scratch Evaluation of Surface Treated Copper Wire -NANOVEA

The UMT-2 tribometer for the wear test, scratch test and small punch

They are solid brass, which means they are soft enough to cleaning or deburring with no scrach. Versatile kit & Commonly used for: Commonly used for

Brass Wire Wheel Brush Kit for Drill,Crimped Cup Brush with 1/4-Inch Shank,0.13mm True Brass Wire,Soft Enough to Cleaning or Deburring with Less

testing-the-limit

Materials, Free Full-Text